GENERAL

In the case where there is dust laden gases containing fine particulates (less than 10μm) from various processes (such as power generation, cement manufacturing or application in mineral processing applications), or the dust laden gases are considered to be of low resistivity, a dry ESP application is not suitable. Rather, Fabric Filter technology has been the technology of choice. Fabric Filters are known to achieve targets of 99 percent collection efficiency or better, which is even more necessary given that tighter emission targets (<10μm) that are set to be introduced soon.

TECH BRIEF

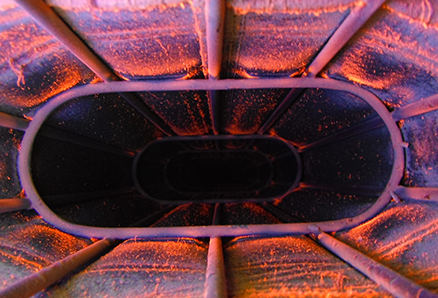

Fabric Filters work differently to ESPs. In ESPs the dust particulates are electrically charged and collected. In Fabric Filters, the dust laden gases flow through a suitable porous layer of fabric or felt, which in turn collects small and sub-micrometer particles. These accumulate and build the external cake wall, which becomes the ongoing filtering process. The pulsing system is then used to regulate cake wall build up on the bag fabric.

Depending on the application, MAIRS Technology has the ability to offer our high volume low pressure (HVLP) reverse air pulse jet filter technology, or typical low volume high pressure (LVHP) pulse jet filter. These range in size depending on the application.

BENEFITS

Is your ESP not performing at the efficiency required? CAPEX and OPEX costs become higher every year as the ESP is coming to the end of its life. Why not speak to us to see if your ESP is suitable for fabric filter conversion? Some of the benefits are:

- Lower clean gas dust emissions

- Lower pressure drop across the system due to improved cleaning and economical bag design/selection for the application

- Lower CAPEX and minimal OPEX costs with fewer replacement parts and minimal required yearly shutdowns

MAIRSTech has years of experience in working with fabric filter technology. Contact us, your leading industry specialists, to discuss our range of services including: performance improvements; spare parts needs; and audits/inspections of your current systems.